Online Ultrasonic Sludge Interface Meter T6080

The Ultrasound Sludge Interface sensor can be used to continuously and accurately determine the Liquid Level. Stable data, reliable performance; built-in self-diagnosis function to ensure accurate data; simple installation and calibration.

The online Ultrasound Sludge Interface Meter is an online analytical instrument designed to measure the Sludge Interface of water from waterworks, municipal pipeline network, industrial process water quality monitoring, circulating cooling water, activated carbon filter effluent, membrane filtration effluent, etc. especially in the treatment of municipal sewage or industrial wastewater. Whether evaluating activated sludge and the entire biological treatment process, analyzing wastewater discharged after purification treatment, or detecting sludge concentration at different stages, the Sludge Interface meter can give continuous and accurate measurement results.

85~265VAC±10%,50±1Hz,power consumption ≤3W;

9~36VDC,power consumption:≤3W;

Liquid Level: 0~5m, 0~10m, 0~20m

Online Ultrasonic Sludge Interface Meter T6080

Measurement mode

Calibration mode

Trend chart

Setting mode

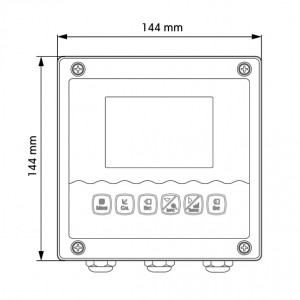

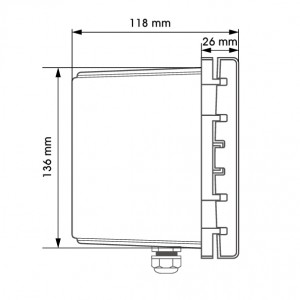

1.Large display, standard 485 communication, with online and offline alarm, 144*144*118mm meter size, 138*138 hole size, 4.3 inch large screen display.

2.The data curve recording function is installed, the machine replaces the manual meter reading, and the query range is arbitrarily specified, so that the data is no longer lost.

3.Real-time online recording of Sludge Interface, temperature data and curves, compatible with all water quality meters of our company.

4.0-5m, 0-10m, a variety of measuring ranges are available, suitable for different working conditions, the measurement accuracy is less than ±5% of the measured value.

5.The new choke inductance of the power board can effectively reduce the influence of electromagnetic interference, and the data is more stable.

6.The design of the whole machine is waterproof and dustproof, and the back cover of the connection terminal is added to extend the service life in harsh environments.

7.Panel/wall/pipe installation, three options are available to meet various industrial site installation requirements.

Electrical connection The connection between the instrument and the sensor: the power supply, output signal, relay alarm contact and the connection between the sensor and the instrument are all inside the instrument. The length of the lead wire for the fixed electrode is usually 5-10 meters, and the corresponding label or color on the sensor Insert the wire into the corresponding terminal inside the instrument and tighten it.

| Measurement range | 0~5m, 0~10m (Optional) |

| Measurement unit | m |

| Resolution | 0.01m |

| Basic error | ±1%F.S |

| Temperature | 0~50 |

| Temperature Resolution | 0.1 |

| Temperature Basic error | ±0.3 |

| Current outputs | Two 4~20mA,20~4mA,0~20mA |

| Signal output | RS485 MODBUS RTU |

| Other functions | Data record &Curve display |

| Three relay control contacts | 5A 250VAC,5A 30VDC |

| Optional power supply | 85~265VAC,9~36VDC,power consumption≤3W |

| Working conditions | No strong magnetic field interference around except the geomagnetic field. |

| Working temperature | -10~60 |

| Relative humidity | ≤90% |

| Waterproof rating | IP65 |

| Weight | 0.8kg |

| Dimensions | 144×144×118mm |

| Installation opening size | 138×138mm |

| Installation methods | Panel & wall mounted or pipeline |

CS6080D Ultrasonic sludge interface sensor

|

Model NO. |

CS6080D |

|

Power/Signal Output |

9~36VDC/RS485 MODBUS RTU |

|

Measure methods |

Ultrasonic wave |

|

Housing material |

304/PTFE |

|

Waterproof grade |

IP68 |

|

Measurement range |

0-5/0-10m (Optional) |

|

Measuring blind zone |

<20 cm |

|

Accuracy |

<0.3% |

|

Temperature range |

0-80℃ |

|

Cable length |

Standard 10m cable |

| Application | Sewage, industrial water, river |

When selecting the sensor installation location, the following criteria should be followed:

●Keep the sensor perpendicular to the mud surface and the bottom of the pool.

●There should be no obstacles in the transmitting range directly below the probe to avoid the ultrasonic signal being blocked and reflected by obstacles.

●The probe should be installed away from gas foam and active floating solids caused by sudden flow rate to ensure accurate and stable measurement.

●The probe should be installed away from the inlet and outlet.

●The sensor probe should be completely submerged in water. If the wall is vertical up and down and the surface is flat, determine the distance from the wall according to the table below.

●If the pool wall is uneven, or there are supports, pipes and other objects, it is necessary to increase the distance from the pool wall, in order to avoid the interference caused by the above objects to the measurement.